Dwell Home

|

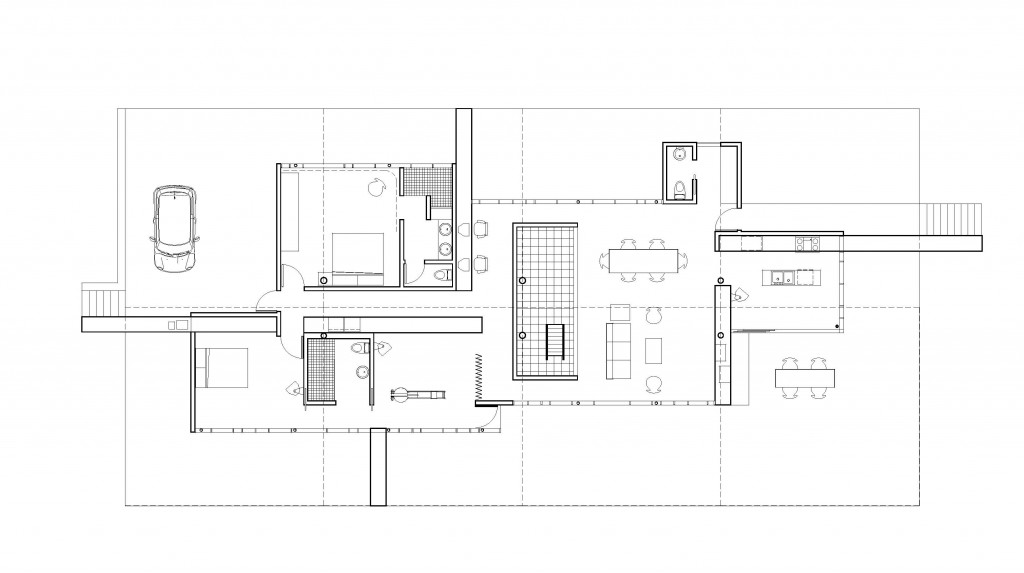

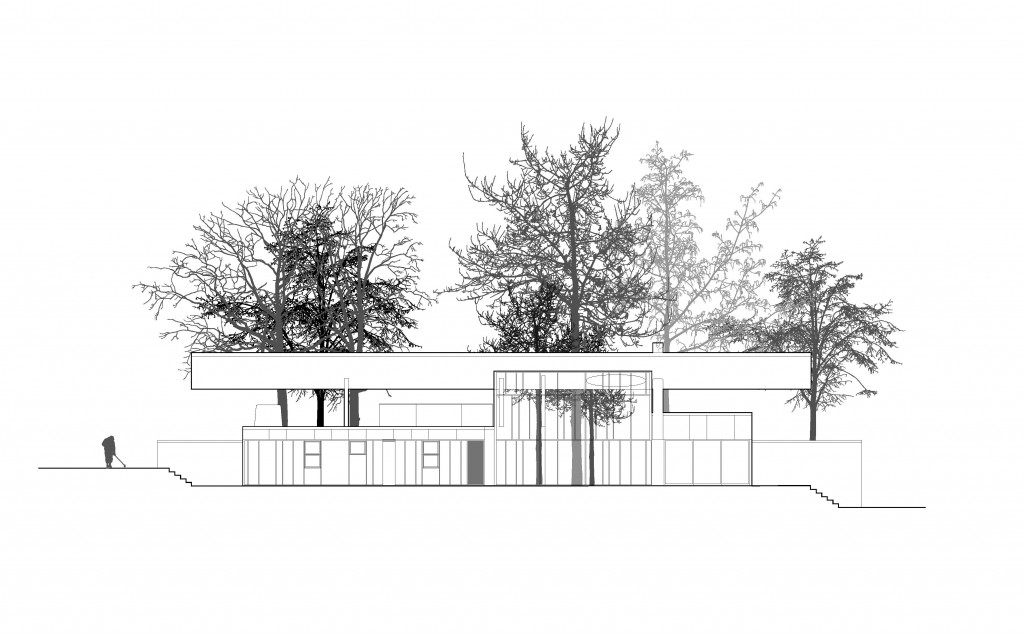

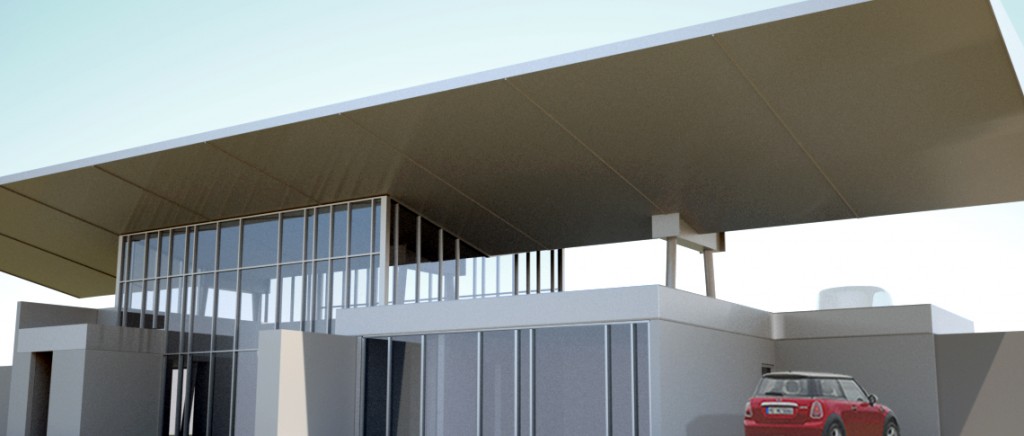

Dwell Home Invitational Throughout the history of modern architecture, mass production, mass customization, and prefabrication have been explored as answers to the problem of affordable housing. As a closed system of logic, the result was either an end product that aspired to a stylized image of the future, or an application of means that were limited by the mode of repetitious factory production, coupled with a certain indifference to site and situation.The chic style of the mass production house as a machine repeated in the landscape, or as a well proportioned box supported on thin columns is over. While the question has been deeply problematized and the solutions interesting in their logics, architecture has failed to magically spring from their techniques, more often than not reducing the problem of dwelling to one of containment. Beyond the aesthetic and the limitations of more conventional means of production, the problem of the prefabricated dwelling persists, provoking more productive possibilities. Today mass customization has become more integrated with mass production, and the effects have made room for an intense optimism. New developments have afforded us the possibility to parse the problem in a different way, to exploit the idea that different parts of a building might be conceptualized according to different means of production. The variable prototype model (VPM) works across a spectrum of means, ranging from the mass produced and the generic, to the customized and innovative use of prefabricated systems, and to the specialized deployment of in-situ components. In order to engineer performance and innovate economically, key elements of the building are separated to clearly define their production/assembly roles. The VPM deploys and integrates these four levels of building production technology into their particular circumstances, realizing economies in some areas to liberate architecture in others. Our proposition structures these themes together. In concert they afford and maximize a diversity of use, occupation, and modes of living within a scaffold of means as opposed to ends. As a lively interplay between constants and variables, the architecture of the VPM Home is uniquely situated. As a fantastic act of architecture, it is again capable of enabling the joy of living, manifesting the ineffable and the deep complexity of dwelling as a human condition. Project credits:

|